In car production, industrial manipulators have become indispensable tools in the automotive final assembly process.

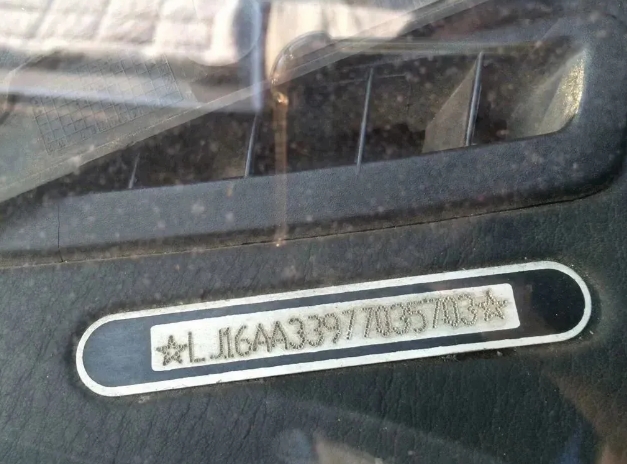

CAR VIN – THE VEHICLE IDENTIFICATION NUMBER

Just like we all have identification cards, cars also have their own unique identifier, called a Vehicle Identification Number (VIN). Every car that rolls off the production line is stamped with a VIN, providing it with a globally unique identity. This number stays with the car throughout its life, tracking its registration, insurance, inspection, maintenance, and repairs.

Where Can You Find the VIN on a Car?

The VIN is usually located in highly visible areas such as the lower left corner of the front windshield, the vehicle identification plate, the engine bay, or the trunk. Additionally, it may be found on the driver’s side door hinge pillar, door lock post, or on the edge of the driver’s side door.

Today, we’re introducing an application designed to make VIN marking on car frames simpler and more ergonomic using an industrial manipulator.

VIN Marking Industrial Manipulator for Automotive Manufacturer

Our client, a major automotive manufacturer, required a solution to mark VIN codes on vehicle frames. This task involved manually handling a VIN marking device weighing up to 25 kg, which was cumbersome and physically demanding for workers. Additionally, the variance in panel surfaces, weld points, and positioning tolerances made it difficult to maintain consistent distance between the marking machine and the marking surface.

To address these challenges, we provided a VIN Marking Industrial Manipulator.

Features of the VIN Marking Industrial Manipulator

- Continuous Vehicle Movement: The car body moves along the assembly line at a steady pace.

- Manipulator Standby: The VIN manipulator waits at its designated “park position” for the vehicle to arrive.

- Engagement with Vehicle Frame: Once the vehicle reaches the activation line, the operator releases the brake and moves the VIN marking device to the marking location on the frame.

- Line-Following Mode: The operator engages the VIN manipulator to move along with the vehicle and aligns the marking tool with the correct spot, then locks it in place.

- VIN Marking Execution: The operator starts the VIN marking process.

- Completion in 15-20 Seconds: The VIN marking process completes within 15-20 seconds, after which the system indicates that the task is done.

- Release and Return: The operator releases the locking mechanism and moves the manipulator away from the car, following the return path.

- Back to Standby: The manipulator is returned to the “park position” and the brake is locked, ready for the next vehicle.

The industrial manipulator used for this application features complete load balancing, smooth movement, and structural rigidity. This allows the operator to handle the heavy VIN marking device with ease�lifting, pushing, and maneuvering it as if it were as light as a pen. This creates a seamless, effortless workflow for this production step.

Liftoal: Your Expert Partner in Industrial Handling Solutions

Liftoal is a trusted partner in industrial lifting and handling equipment, offering customized solutions to meet diverse operational needs. With over two decades of experience, Liftoal specializes in advanced labor-saving handling technologies that enhance efficiency, safety, and precision across various industries. Whether you need solutions for lifting heavy machinery, moving bulk materials, or optimizing assembly processes, Liftoal has the expertise and technology to support your manufacturing and logistics operations.

Contact Liftoal today for expert advice on selecting the right industrial lifting and handling equipment tailored to your specific requirements. Optimize your production processes and enhance workplace safety with Liftoal�s advanced solutions!