Industrial manipulators are indispensable pieces of equipment in automotive final assembly, offering improved efficiency, quality, and ergonomics on the production line.

Why Is Door Disassembly Important?

After the car body leaves the paint shop, with all parts coated in fresh paint, the first step upon entering the assembly line is to remove the doors. This allows the doors to be sent down a separate line for assembly of interior components, wiring, and other fittings, before being reassembled onto the main vehicle body.

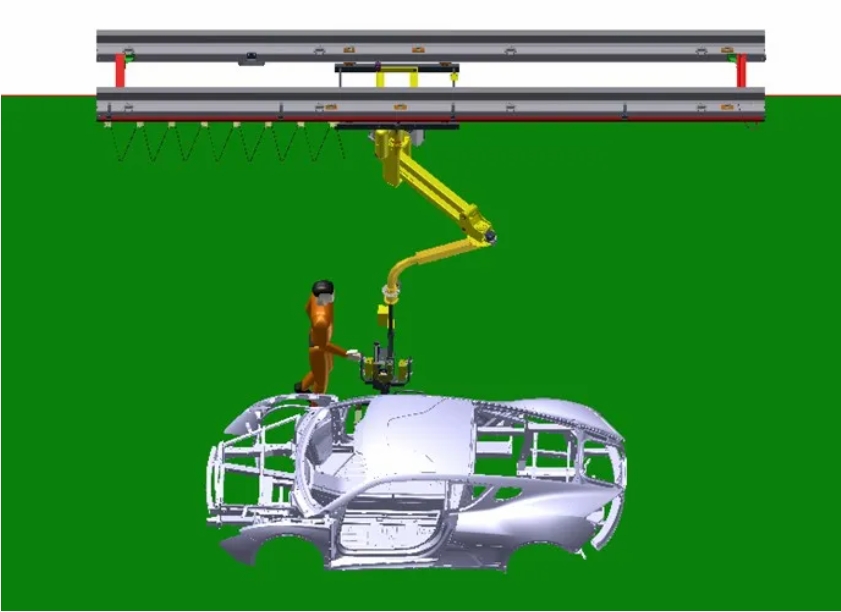

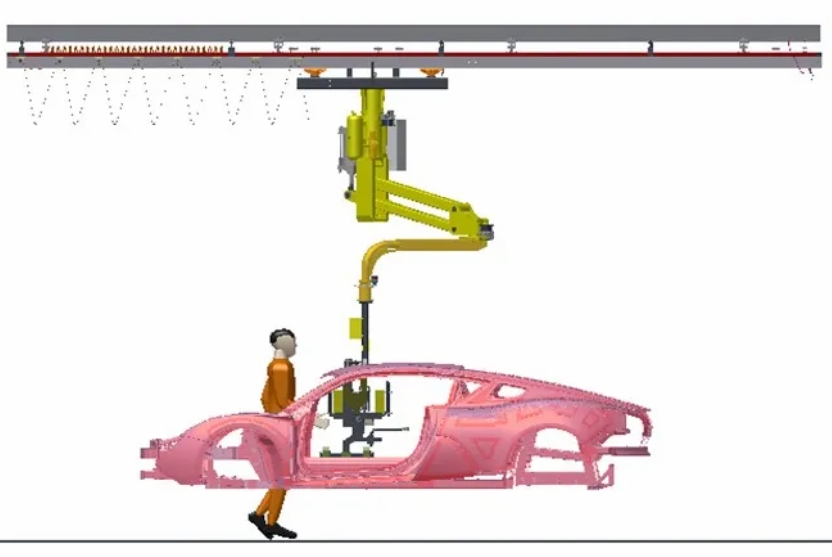

Door Disassembly Manipulator System Overview

In modern automotive production, traditional indicators like the weight of a part (e.g., whether it exceeds 15 kg) are no longer the main criteria for deciding whether to use manual handling or industrial lifting equipment. Instead, priorities have shifted towards:

- Quality: Ensuring zero defects. The weight of parts must not impact product quality.

- Production Rate: Constantly striving for higher output, pushing beyond traditional benchmarks like 60 Jobs Per Hour (JPH) towards targets like 70 JPH or even 85 JPH.

- Process Optimization: Repeated analysis and optimization of every detail.

Car Door Characteristics

Passenger car doors vary significantly in style, size, and weight depending on the make and model. Typical dimensions are:

- Width: 1200�1500 mm

- Height: 1400�1600 mm

- Thickness: 200�350 mm

- Weight: 22�26 kg

Manipulator Configuration

- Track System: “Low-Damping” Aluminum Track, 7m x 2 rails

- Trolleys: Manual pull-type trolleys

- Main Unit Model: PBF-SM100

- Main Unit Specifications:

- Rated Load: 100 kg

- Service Radius: 2500 mm

- Working Stroke: 1200 mm

- Gripper Type: Powered gripper

- Control System: Automatic load/unload mode switching

- System Working Pressure: ?0.6 MPa

- Air Consumption: 300 L/min

- Quantity: One manipulator per side, two in total

Manipulator Features

This industrial manipulator system is designed to simplify door disassembly. It employs a specialized powered gripper and an automatic balance control system that keeps the load in a floating state throughout the working range, enabling precise positioning.

Track System

- The modular track system allows for easy on-site adjustment and installation in various settings.

- Low-damping aluminum alloy tracks provide excellent wear resistance and strength, ensuring smooth, low-resistance, and noise-free operation. The system is safe to use and maintains a clean appearance.

Main Body

- The PBF main unit uses the principle of force balance, keeping the load in a weightless floating state for easy, precise positioning.

- Smooth movement and rigid structure ensure effortless material transfer and assembly.

- The automatic load/unload switching system allows the manipulator to maintain balance whether loaded or unloaded, enhancing ease of operation.

- The main unit includes a safety mechanism to prevent the manipulator arm from dropping in case of a sudden loss of air supply.

- The misoperation protection feature ensures that the workpiece can only be unloaded when properly supported, ensuring safe operations.

Gripper Features

- The gripper is specifically designed for car door disassembly, providing ergonomic handling.

- Powered gripper mechanism allows for easy grasping and handling of the car door.

- The system features a load indicator that turns red when a load is detected, providing visual feedback.

- Misoperation protection ensures safe unloading, and soft protective materials and shields are included to prevent scratches on the workpiece.

- Control handle is integrated with the custom gripper for dual-hand operation, enhancing material positioning precision.

Safety Features

- Anti-Drop Safety Cables: Prevent accidental drops in case of failure.

- Hydraulic Buffers: Limit the track ends to prevent collisions.

- Warning and Emergency Stops: The system integrates with the main line to create a safe interaction mechanism. Limit switches at the end of the track trigger a warning buzzer when approached, and stop the main line if further contact occurs.

- Mechanical Stops: Four mechanical stops ensure safe operation.

Liftoal: Your Expert Partner in Industrial Handling Solutions

Liftoal is a trusted partner in industrial lifting and handling equipment, offering customized solutions to meet diverse operational needs. With over two decades of experience, Liftoal specializes in advanced labor-saving handling technologies that enhance efficiency, safety, and precision across various industries. Whether you need solutions for lifting heavy machinery, moving bulk materials, or optimizing assembly processes, Liftoal has the expertise and technology to support your manufacturing and logistics operations.

Contact Liftoal today for expert advice on selecting the right industrial lifting and handling equipment tailored to your specific requirements. Optimize your production processes and enhance workplace safety with Liftoal�s advanced solutions!